Local Exhaust Ventilation:

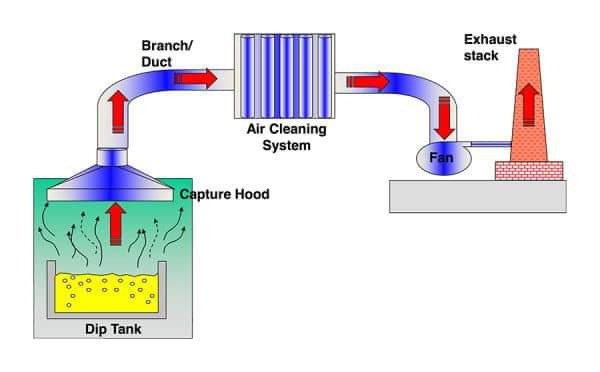

Local exhaust ventilation (LEV) is a system designed to reduce exposure to airborne contaminants such as dust, fumes, vapors, and gases in a workplace. It captures pollutants at or near their source before they can disperse into the work environment and be inhaled by workers. Here’s a breakdown of its key components and functions:

- Hood: The part of the system where contaminants are captured. It is positioned close to the source of the contaminant release to ensure maximum capture efficiency.

- Ducting: Channels that transport the captured air and contaminants away from the hood to the air-cleaning device.

- Air-cleaning device: Filters or other devices that remove the contaminants from the air. Common types include fabric filters, electrostatic precipitators, and scrubbers.

- Fan: The component that moves the air through the system. It creates the necessary suction to draw contaminated air into the hood and through the ducting to the air-cleaning device.

- Discharge: The point where the cleaned air is released into the environment or returned to the workplace, depending on the system design and regulations.

Benefits of LEV:

Health Protection: Reduces workers’ exposure to harmful substances, thereby protecting their health and well-being.

Compliance: Helps workplaces comply with occupational health and safety regulations.

Environment: Reduces the release of contaminants into the broader environment, contributing to overall environmental protection.

Applications of LEV:

Industrial Settings: Factories, foundries, welding shops, and chemical plants.

Laboratories: Handling of hazardous substances in fume hoods.

Woodworking: Dust extraction from woodworking machinery.

Construction: Control of dust and other pollutants during demolition and building activities.

Regular maintenance and monitoring are crucial to ensure that LEV systems function effectively and continue to protect workers from exposure to hazardous substances.

Leave a comment